Product features

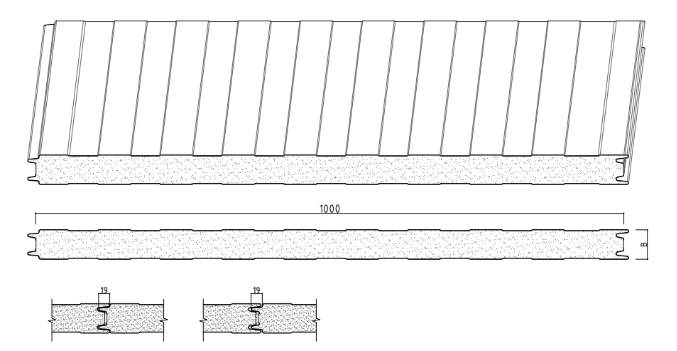

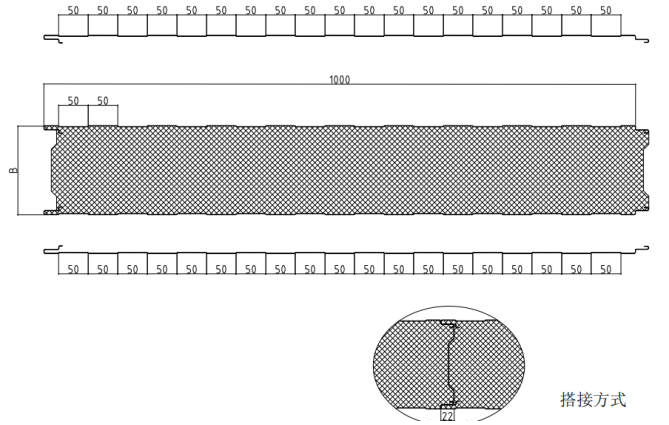

The concave convex groove structure improves the insulation and air tightness of the plate joints, which is specially designed for cold storageApplication

pu cold room panel is widely used in food, supermarkets, hotels, aquatic products, pharmaceutical, biological, chemical, industrial and mining enterprises and other industries. It can be customized according to customer requirements and library features, the constant pursuit of excellence, has the ability to meet the special requirements of customers, to win customer satisfaction.| ITEM | SPECIFICATION | |||

| Product Name | Cold storage panel/cold room panel/cooler panel | |||

| Structure | PPGI + Polyurethane foam + PPGI | |||

| Effective | 1000mm | |||

| Panel Thickness | 50mm、75mm、100mm、120mm、150mm、200mm | |||

| Length | Generally 1-11.9m,according to the design,transportation or installation conditions | |||

| Core material | Rigid polyurethane foam | |||

| Density | 40-45kg/m3 | |||

| Thickness of steel | 0.3-0.8mm | |||

| Color | Blue、White Grey and other colors in RAL | |||

| Thermal | 0.023% W/(m·K)Maximum | |||

| Enclosed rate | 95% Maximum | |||

| Flame resistance | Gread B | |||

| Usage life | Over 20 years | |||

| The technical specification of cold storage sandwich panel | ||||

| Thickness range | Temperature difference between inside and outside | Height of wall panel | Lenght of roof panel | Applicable cold storage temperature |

| mm | ℃ | m | m | ℃ |

| 100 | 30 | 5 | 4.45 | -15 |

| 125 | 35 | 5.5 | 5.2 | -20 |

| 150 | 50 | 6 | 5.85 | -25 |

| 175 | 65 | 6.5 | 6.3 | -30 |

| 200 | 75 | 7 | 6.8 | -40 |

| ·The data shown in the left table are only avialiable for the panel which subjectto the internal-external pressure difference and contraction pressure,without wind load.if the specified length/height is exceeded or wind load occurs,panel supporters are required. | ||||

| ·The above data are calculated according to the heat flow of 8-10W/m2. | ||||

PU sandwich panel

The polyurethane cold room panel is composed of two galvanized steel sheets and rigid polyurethane foam in the middle. Because the polyurethane cold room panel has several outstanding advantages, such as thermal insulation, waterproof, light weight and fast installation, It has been widely used as the building material of cold storages, cool rooms, clean rooms, free-dust workshops and exterior walls in cold places.

cold storage (PU) sandwich panel

| Product number | HC-M2L-PU/PIR |

| Panel type | cold storage panel |

| core material | polyurethane/PU |

| Pull seam of outer plate | 2mm |

| panel of the thickness | 100mm/150mm/200mm |

| Surface Appearance | Flat/Small ripple/Square wave/Orange peel/Other |

| width of the panel | 1000mm |

PIR/PUR Sandwich panel

PIR Polyisocyanurate is called PIR for short. For the composite boards developed, excessive isocyanurate is added and ring structure and higher isocyanurate index are employed in the compounds to form compact PIR products, thus ensuring greater stability and excellent heat and fire resistance for the internal rigid foams. Experiments show that the products can endure a temperature up to 200℃ in short time period or to 160℃ for long time. PUR In terms of raw material proportioning and process output, PUR products employ the globally advanced six component online automatic (SIMENS) mixing and pouring technology and have realized six-component continuous foaming for the first time in China. With the technology, mixing and proportioning process may be finished in an online way;the formula may be adjusted according to environmental changes; air feeding and mixing devices may be used to make raw material mixing more even and foam finer, thus producing high-strength, energy-saving and environment friendly building boards.cold storage (PIR/PUR) sandwich panel

| Panel type | cold storage panel |

| core material | PIR/PUR |

| Pull seam of outer plate | 2mm |

| panel of the thickness | 100mm/150mm/200mm |

| Surface Appearance | Flat/Small ripple/Square wave/Orange peel/Other |

| width of the panel | 1000mm |